Ensuring building safety through standardized tests.

In-depth steel testing services, ensuring structural integrity, quality control, and compliance for construction projects.

We are the best at construction material testing

and our services help provide safety for projects:

- Commercial

- Residential

- Educational

- Hospitals

- Bridges & Roads

- Oil/Gas/Mining

Benefits of Steel Testing

Benefits of Steel Testing

To determine the durability

of Steel in construction

Quality

Accurate assessments, reliable results, ensuring quality.

Safety

Building trust through rigorous safety assessments and testing.

Efficacy

Evaluating construction material efficacy effectively.

Endurance

Ensuring materials endure in construction projects.

Reinforcing Steel Bars

Reinforcing Steel Bars

Reinforcing Steel Bars

Extensive testing services for reinforcing steel bars, assessing

strength, ductility, corrosion resistance, and adherence to construction standards for reliable and durable reinforcement in structures.

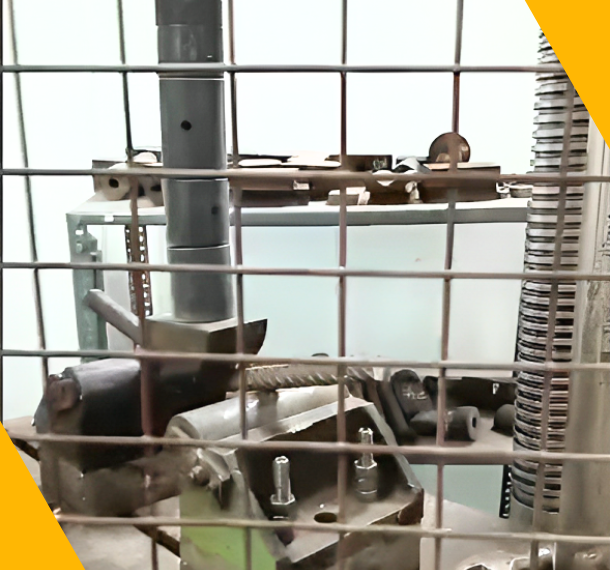

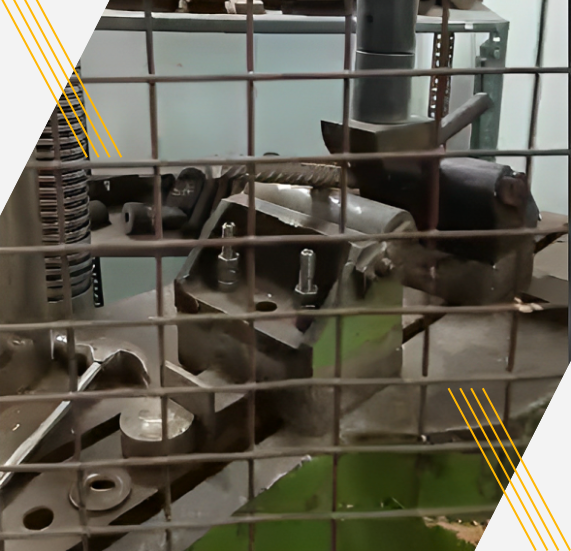

Procedures of evaluating reinforced steel bars:

- Bend Test

- Rebend Test

- Tension Testing

- Coating Thickness Test

- Chemical Testing

Bend Test

Benefits of evaluating steel bend test:

- Ductility Assessment

- Quality Assurance

- Material Consistency

- Process Validation

- Defect Detection

- Performance Prediction

Rebend Test

Rebend Test

Rebend Test

The Rebend Test in steel testing assesses the ability of a previously bent steel specimen to withstand additional bending without fracture.

This test ensures the material's ongoing ductility, verifying its suitability for applications requiring flexibility, such as construction and structural projects, and confirming compliance with industry standards.

Have any upcoming projects?

Coating Thickness

Coating Thickness

Coating Thickness

Evaluating coating thickness is crucial for the durability of the steel. A dependable coating thickness gauge is one of the most vital tools that helps in controlling material costs, managing application efficiency, maintain finish quality and ensuring adherence to contract specifications for steel.

Testimonials

Testimonials

Our clients reviews.

Having Questions

Having Questions

FAQ's

Need more details?

Need more details?